WHAT IS A DIGITAL TWIN?

A Digital Twin is a virtual replica of a physical object, device, or process. Digital twin technology enables real-time monitoring, analysis, and testing through simulations that mirror real-world conditions.

In education and vocational training, digital twins allow learners to experience real-life scenarios in a safe, cost-effective, and repeatable way. Since real-world conditions are recreated in virtual environments, learning becomes faster, more effective, and long-lasting.

With this technology:

Physical processes can be monitored,

Performance and efficiency can be analyzed,

Different scenarios can be tested safely.

SOFTWARE SOLUTIONS

01

Digital Content Platform

The digital twin–based content platform provides unlimited scenarios and applications inspired by real-world conditions, enriching learners’ experiences. Accessible via personal computers and digital twin hardware, the platform brings flexibility to the learning process and allows users to practice anytime, anywhere.

Its adaptable structure ensures that training can be instantly tailored and integrated into different fields of education. Learners can continue their training both in school and at home with ease.

02

Digital Twin Training Module

The training modules present theoretical knowledge, practical application, and examination stages within a layered structure. Lessons supported by 3D models and animations make the learning process both visual and interactive. User performance is tracked in real time, and measurement is carried out reliably through automatic assessment and reporting processes. In this way, the knowledge acquired is reinforced directly with practice through applications that resemble real maintenance and repair scenarios.<

03

Teacher Cockpit

The management panel provides administration and reporting of all user screens and processes. Instructors can manage the digital twins in the school laboratory through this panel, instantly see which user is in which digital twin and which steps they are following, and remotely intervene in the digital twin system that the student is working on. The ability to provide instant intervention and visual performance analysis offers quick feedback to the educational process while making detailed reporting.

HARDWARE SOLUTIONS

Digital Twin Systems

- It precisely replicates real-world physics and device functions.

- The tools, equipment, and maintenance-repair processes found in physical environments operate according to the same principles in their digitalized versions.

- With its ability to receive, transmit, and process data, it provides an experience very close to real-world applications.

- Digital Twin Systems deliver unmatched accuracy by replicating real device functions, vehicle maintenance-repair processes, physical scenarios, and the laws of physics with only a 1/10¹⁶ margin of error.

- In this way, users can combine theoretical knowledge with real-world applications and effectively develop their practical skills.

01

Electric Vehicle Maintenance & Repair

The Digital Twin Automotive Maintenance Bench enables students to practice fault diagnosis and repair training in an interactive environment.

A real diagnostic scanner is connected to a digital twin vehicle.

Learners use physical tools such as multimeters and testers to identify faults and replace components.

The process is simulated without material consumption or safety risks.

Through randomized fault assignments, learners improve their problem-solving skills and prepare for real-world scenarios in electric vehicle maintenance.

02

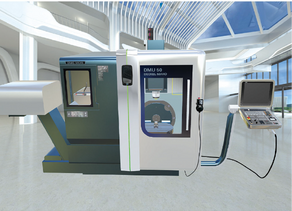

CNC Digital Twin

he CNC Digital Twin integrates digital machining centers with real CNC machine NC units and manual control wheels.

The system replicates machining processes with high accuracy using digital twin data modeling and processing algorithms.

Learners can perform manual or automated programming via interactive panels.

Expensive consumables (cutting tools, workpieces, servo systems) are simulated, eliminating cost and safety concerns.

It supports customization across multiple CNC models, offering 27 machining centers and 13 control panels within a single device for a comprehensive CNC training environment.

03

PLC and Electrical-Electronics Digital Twin

This system connects a physical PLC to a digital twin production line, allowing learners to operate processes as they would with real equipment.

Learners experience tactile feedback from operating the physical PLC.

The production line is recreated with digital twin technology, ensuring zero material waste and no safety hazards.

Each device supports training in electrical circuits, mechatronics, pneumatics, hydraulics, digital and analog electronics, microcontroller applications, design, and fault detection.

04

Industrial Robotics Digital Twin

The Digital Twin Robotics Workbench allows students to program and control digital twin robots using a physical Robot Teaching Pendant. The teaching pendant provides tactile feedback, while the robot itself is recreated through digital twin technology.

The training process is conducted safely and cost-effectively without material consumption. The system supports switching between different robot models such as KUKA, ABB, and FANUC, enabling customization in the training process and preparing students for diverse industrial scenarios.